Fire Rated System

Application Instructions for Cedar Shakes

INSTRUCTIONS FOR APPLYING FSR TREATED PRODUCTS. SHAKES AS A CLASS "A" ROOF COVERING SYSTEM

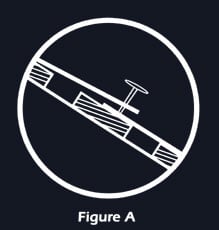

FSR Treated Products Class "B" labeled cedar shakes must be applied over one layer of 72-pound mineral surfaced cap sheet or ¼" thick Dens-Deck Roof Board manufactured by Georgia Pacific Corporation. Fastener length must be increased for the thickness for the Dens Deck board or the cap sheet. The mineral surfaced cap sheet is installed mineral surface side up with 2" (51 mm) overlaps on sides and ends, and attached with sufficient number of fasteners to hold the sheet in place prior to installation of the shakes. If installed on spaced sheathing the horizontal overlap must meet on the solid nailing surface. (See figure A). Dens-Deck boards are fastened to spaced or solid sheathing using a minimum of four fasteners to avoid panel shifting prior to the installation of the shakes. If installed on spaced sheathing the horizontal joints of the Dens-Deck must meet on the solid nailing surface.

Roof Pitch and Exposure

Handsplit shakes should be used on roofs where the slope or pitch is sufficient to ensure good drainage. Minimum recommended pitch is 1/6" or 4:12 (4" vertical rise for each 12" horizontal run). Maximum recommended weather exposure is 10" for 24" shakes.

Roof Application

Along the eave line, a 36" wide strip of Type 30 roofing felt is laid over the sheathing. The beginning or starter course at the eave line should be doubled. After each course of shakes is applied, an 18" wide strip of Type 30 roofing felt is laid over the top portion of the shakes extending onto the sheathing, with the bottom edge of the felt positioned at a distance above the butt equal to twice the weather exposure.

Fasteners

Hot dipped zinc coated nails or stainless steel staples are recommended. However, any U.B.C. approved corrosion resistant fasteners can be used. Use two for each shake placing them approximately 1" from each edge, and high enough to be covered an inch or two by the succeeding course. Fasteners should be long enough to penetrate at least ¾" or through the sheathing. The butts of the shakes should project from 1 ½" to 2" from the first roof board so that the rainwater will spill into the gutter or to the ground without working down the side of the building. Individual shakes should be spaced about ¼" to ¾" apart to allow for possible expansion. These joints or spaces between shakes should be broken or offset at least 1 ½" in adjacent courses and should be kept out of direct alignment in alternate courses.

WARNING: Both raw and fire retardant treated cedar products contain a level of tannic acid that can cause corrosion to unprotected metals and concrete surfaces. Pre-painted galvanized or pre-painted aluminum gutters are recommended. Initial water run-off over both raw and fire retardant cedar can cause staining. A low-pressure wash of the roof immediately after application recommended. Chemco is not responsible for any direct or indirect damages caused by water run-off.